Coke tar residue introduction

Coke tar is industrial solid waste, which produced in the coking process, mainly from mechanized tar ammonia clarification tank, tar super centrifuge, coke tar ammonia separation tank in the gas purification system. With the continuous expansion of production capacity and coal conditioning process, the amount of coke tar produced will gradually increase, coke tar residue with a sticky, odor characteristics, is troubled coking industry on the tar treatment and transportation.

Production description

After a series of research and development, and the test, our company made the current patented coke tar residue system products. The coke tar residue is transported by a special hopper, and then mixed with the pulverized according to a certain proportion in a sealed conveying and mixing apparatus.

Product features

The kind of the mixture material is re-cooking, that will improve the coke and gas production to some extent, which not only curb environment pollution caused by coke tar, but also save costs and reduce waste.

Advantages

The device used of pipeline transportation, low investment costs, tidy of the operation site, a small area covered, mixed effect very well (can be mixed to adjust the proportion of the two), mature equipment system, high stability, low maintenance costs. The device adopts pipeline transportation, PLC control system, integrated management, to achieve the free ratio of the coal and coke tar residue, low operating costs, safe and reliable, high efficiency, while changing dirty, chaotic, poor operating environment. Avoid environmental pollution. The device structure is reasonable, low energy consumption, easy operation, low investment.

The main process

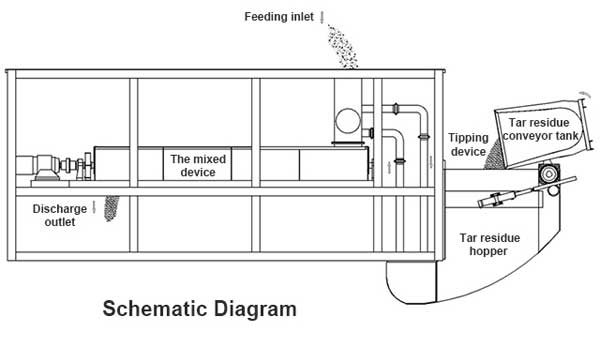

The forklift transports coke tar residue’s storage tank to the processing site, by adopting the flip device to the hopper, coking coal is also conveyed into the mixer, and coke tar is also conveyed into mixer from the hopper by lifting device, after thoroughly mixed, then the return of coking coal conveyor.

Device parameters

Covers about 90 square meters, the total height of about 11 meters; total power of system about 46.5KW, handling capacity of coke tar residue about 1-3t / h. The coke tar residue is a viscous sticky material, the ratio of pulverized coal and tar is 10: 1.

The device used of pipeline transportation, low investment costs, tidy of the operation site, a small area covered, mixed effect very well (can be mixed to adjust the proportion of the two), mature equipment system, high stability, low maintenance costs. The device adopts pipeline transportation, PLC control system, integrated management, to achieve the free ratio of the coal and coke tar residue, low operating costs, safe and reliable, high efficiency, while changing dirty, chaotic, poor operating environment. Avoid environmental pollution. The device structure is reasonable, low energy consumption, easy operation, low investment.

The device used of pipeline transportation, low investment costs, tidy of the operation site, a small area covered, mixed effect very well (can be mixed to adjust the proportion of the two), mature equipment system, high stability, low maintenance costs. The device adopts pipeline transportation, PLC control system, integrated management, to achieve the free ratio of the coal and coke tar residue, low operating costs, safe and reliable, high efficiency, while changing dirty, chaotic, poor operating environment. Avoid environmental pollution. The device structure is reasonable, low energy consumption, easy operation, low investment.