Horizontal Spiral Super Centrifuge

Horizontal Spiral Super Centrifuge Introduction

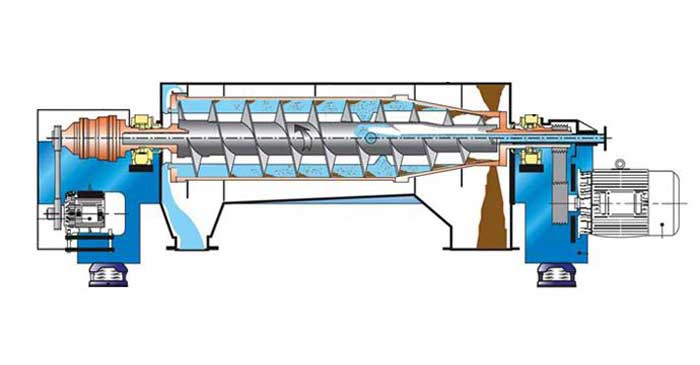

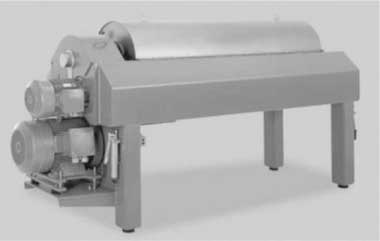

The horizontal spiral super-centrifuge, also called decanter centrifuge, utilizes the principle of centrifugal sedimentation, specifically designed for separating solid-liquid mixtures and isolating solids from liquids or liquid mixtures. The super decanter centrifuge consists of the main body, drum, spiral conveyor, drive device, and control system. Based on the difference in material density, it undergoes settling separation under the action of centrifugal force.

The rotating drum generates powerful centrifugal force, causing rapid separation of the liquid mixture and solid particles. Heavy substances settle on the inner wall of the drum while lighter substances move away from the inner wall. Continuous operation is achieved through the screw conveyor.

super decanter centrifuges' performance technical parameters can be customized according to the requirements of different industries. Currently, it is used in sludge dewatering, sulfur foam, and tar separation, providing assurance for the environmental upgrade of the coking industry. This equipment is widely used for efficient separation, characterized by continuous operation, high processing capacity, low electricity consumption per unit output, and strong adaptability.

Decanter Centrifuge Working Principle

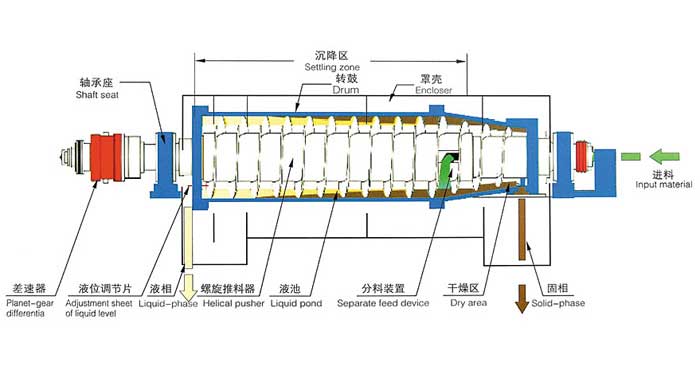

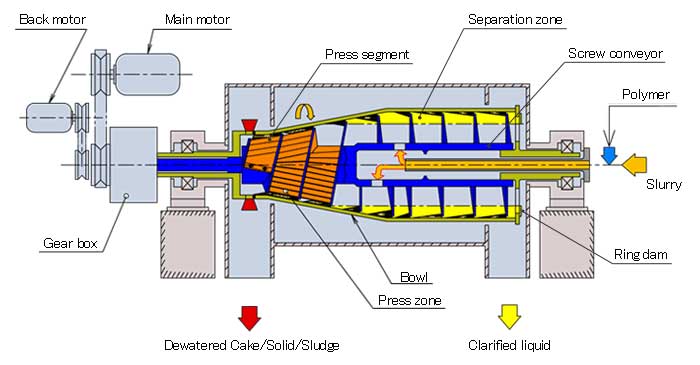

A decanter centrifuge utilizes centrifugal force to continuously separate two-phase or three-phase mixtures of immiscible liquids and solids with different densities. The material to be separated is continuously fed into the spiral core shaft through the inlet pipe. It then enters the high-speed rotating drum through the discharge port of the spiral conveyor. Under the action of centrifugal force, the suspended liquid forms a ring-shaped liquid flow inside the drum, while the solid phase settles on the inner wall of the drum due to centrifugal force. The differential speed between the spiral and the drum, created by the differential, pushes the solid residue to the drying zone at the small end of the drum. After further dehydration, it is continuously discharged from the small end discharge port. As the liquid has a lower density, it forms a liquid ring layer only on the inner side of the solid ring layer. It continuously overflows from the weir plate at the large end of the drum, and is discharged from the drum.

Horizontal Spiral Super Centrifuge Features

This type of centrifuge is designed for separating solid-liquid mixtures by utilizing centrifugal force. It typically consists of a rotating drum or bowl with a spiral conveyor inside. As the mixture is fed into the centrifuge, the high-speed rotation generates centrifugal force, causing the heavier solid particles to settle along the inner wall of the drum while the lighter liquid phase moves towards the center.The spiral conveyor continuously transports the separated solids towards the discharge end of the centrifuge. Horizontal spiral super centrifuges are known for their efficiency in continuous operation, high throughput, and adaptability to various industrial applications, making them widely used in industries such as chemical processing, pharmaceuticals, and wastewater treatment.

Utilization of Centrifuge Dehydration

Purpose:

- Reduce volume

- Lower transportation costs

- Reduce disposal costs

- Increase material stability

- Reduce material heat treatment costs

Performance Parameters:

- Feed: 0.5%-8% solid content

- Solid residue after separation: 70%-85% moisture content

- Flocculant: approximately 2-7g/kg solid content

- Clarified liquid after separation: approximately 0.1% solid content

- Separation efficiency: approximately 97% (depending on the concentration of the material)

Why HENGWEI Decanter Centrifuge

The decanter centrifuge consists of a high-speed rotating drum, spiral, differential, machine body, and electrical control system. The entire machine has a compact structure, occupies a small footprint, and is easy to operate and maintain.Specification of Horizontal Decanter Centrifuge

| Type | HWLW458(two phase) | HWLW350(two phase) | HWLW458(three phase) |

|---|---|---|---|

| Application | Suspension Medium Separation: such as sludge, sulfur paste, etc. | Suspension Medium Separation: such as sludge, sulfur paste, etc. | Suspension Medium Separation: such as soy protein, tar, etc. |

| Rotor | Maximum speed: 3000rpm | Maximum speed: 4200rpm | Maximum speed: 4200rpm |

| Maximum solid density: 2.0kg/dm3 | Maximum solid density: 1.3kg/dm3 | Maximum solid density: 1.6kg/dm3 | |

| Drum inner diameter: 420mm | Drum inner diameter: 350mm | Drum inner diameter: 458mm | |

| Discharge diameter: 245mm | Discharge diameter: 205mm | Discharge diameter: 245mm | |

| Minimum/Maximum medium temperature: 5-80℃ | Minimum/Maximum medium temperature: 5-60℃ | Minimum/Maximum medium temperature: 5-100℃ | |

| Materials in contact with the medium | Drum: SAF2205 | Drum: SAF2205 | Drum: SAF2205 |

| Spiral protection: Tungsten carbide | Spiral protection: Tungsten carbide | Spiral protection: Tungsten carbide | |

| Other equipment: 316L/304 | Other equipment: 316L/304 | Other equipment: 316L/304 | |

| Seal component: FKM/PTEE | Seal component: FKM/PTEE | Seal component: FKM/PTEE | |

| Adjustment | Drum rotation speed: ≤3000rpm | Drum rotation speed: ≤4200rpm | Drum rotation speed: ≤4200rpm |

| Speed difference: 2-10rpm | Speed difference: 2-15rpm | Speed difference: 2-20rpm | |

| Operating mode: Forward | Operating mode: Forward | Operating mode: Forward | |

| Main motor | Power: 30kw | Power: 22kw | Power: 30kw |

| Rated speed: 2995rpm | Rated speed: 1480rpm | Rated speed: 2995rpm | |

| Voltage/frequency: 400V/50HZ | Voltage/frequency: 400V/50HZ | Voltage/frequency: 400V/50HZ | |

| Protection rating: IP55 | Protection rating: IP55 | Protection rating: IP55 | |

| Auxiliary motor | Power: 11kw | Power: 5.5kw | Power: 15kw |

| Rated speed: 1470rpm | Rated speed: 1470rpm | Rated speed: 1470rpm | |

| Voltage/frequency: 400V/15-50HZ | Voltage/frequency: 400V/15-50HZ | Voltage/frequency: 400V/15-50HZ | |

| Protection rating: IP55 | Protection rating: IP55 | Protection rating: IP55 |