Coke Oven Equipment

Coke Oven Coking Process Brief:

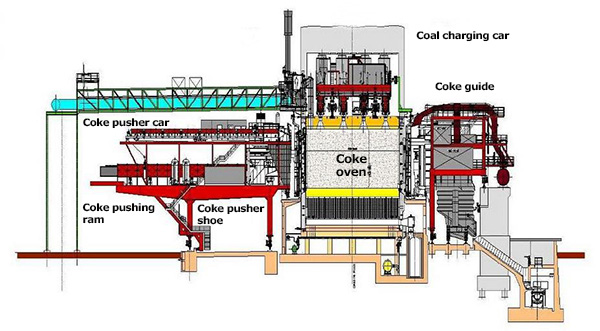

The coke pusher car takes raw coal from the coal tower, stamps and presses them to coal cakes, then pushes the coal cakes into the coking chamber. The coal cakes are coked in the coking chamber for a coking cycle’s high temperature carbonization. After the coal cakes are totally coked inside, the coke will be pushed by the coke pusher car to a coke car through a coke guide. The coke car will be pulled to the coke quenching tower by the electric motor. Following, the quenched coke will be delivered to the cooling coke table for cooling after which the cool coke will be taken to the coke screening station for screening and transportation.

The raw coke oven gas generated in the high temperature carbonization process rises up to the top of the coking chamber and goes through the ascension pipe and the bridge pipe and finally to the gas collecting tube. The 700℃ gas will be cooled to 85℃ by the sprayed ammonia water in the bridge pipe. The gas and congealed tar and ammonia liquor will be inhaled through the gas tube to the recovery plant to be refined and tar recycle.

The refined gas can be conveyed to the cellar after heated to 45℃ by the preheater and conveyed through the lower spout to the combustor. The residue waste gas will be exhausted to air through the flue and stack.

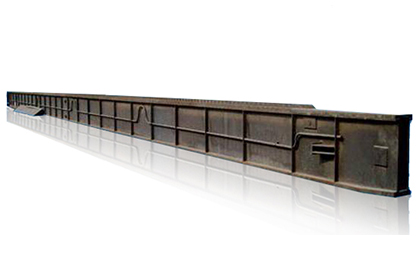

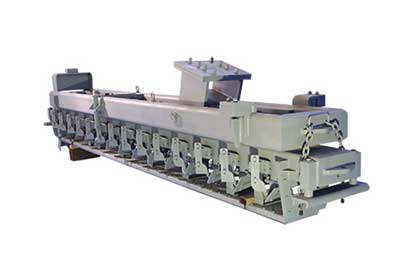

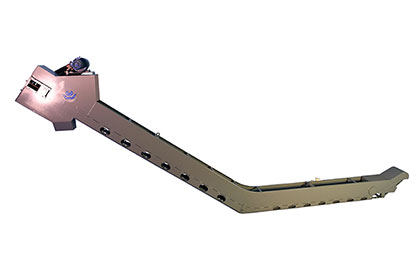

We manufacture and supply coke pushing ram, coke pusher shoe, coke oven door& frame cleaning device, coke spillage system of coke pusher and coke spillage system of coke guide during this process.