Coke Dry Quenching(CDQ) Equipment

CDQ Technical Process

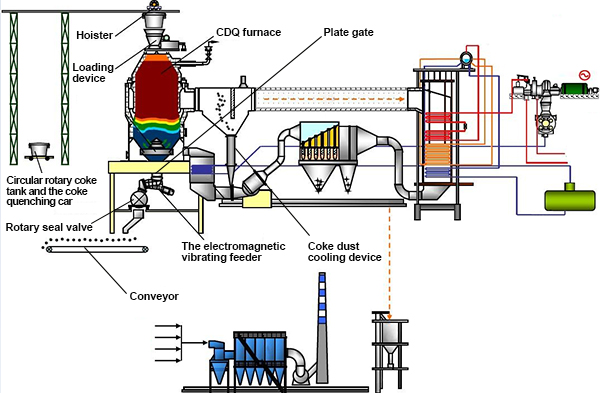

Hot coke out from the coking chamber is received by a circular rotary coke tank on the coke quenching car towed by the electric locomotive. When the car runs to the bottom of the CDQ hoisting headframe, the coke tank is hoisted up by the hoister to the top of the headframe and then moved horizontally to the center of CDQ furnace. During the process, the furnace lid with the charging device as a whole will be automatically opened by the electromotion handspike, and the coke hopper will be automatically stopped over the top of the CDQ furnace. Next, the coke tank is put down by the hoister and received by the coke tank platform of charging device. During the descending process of the hoister, the bottom gate of the coke tank is automatically opened and began to load the hot coke. After the charging process, the hoister will automatically hoist the tank and take it back onto the coke quenching car. Meanwhile, the charging device works automatically to close the lid.

The hot coke charged into the CDQ furnace is stored for a certain time in the pre-stored section. As the discharging process is on, it gradually decreases to the cooling section in which it is cooled by heat exchange with the circulating gas and then go through the electromagnetic vibrating feeder and the rotary seal valve, finally is discharged by the chute and conveyed out by a special belt conveyor. In order to facilitate the maintenance of the belt conveying system and lower the impact on the CDQ production resulting from the maintenance, two sets of the belt conveyors are generally designed: one set is in use, the other is the spare set.

The circulating gas used to cool the coke increases in temperature after the heat exchange with the hot coke in the cooling section of the CDQ furnace, and is discharged by the circular flue out of the furnace. The circulating gas at high temperature will enter the CDQ furnace for heat exchange after the first separation of coarse particles of coke dust by a dust collector. The boiler generates steam, and as the temperature decreases to about 160℃, the circulating gas at low temperature comes out from the boiler. After the second separation of fine particles of coke dust, it is flown into the water preheater by the circulating fan to be cooled to about 130℃. And then it will enter into the CDQ furnace for recycling use.

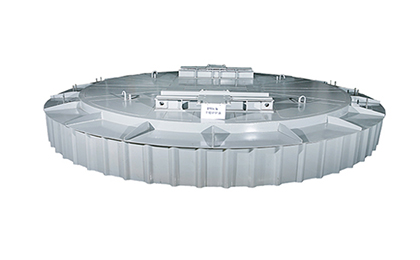

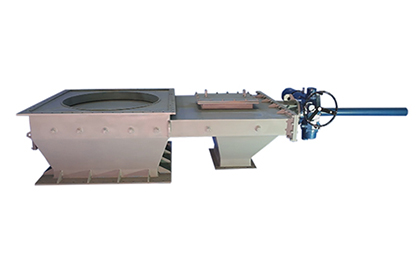

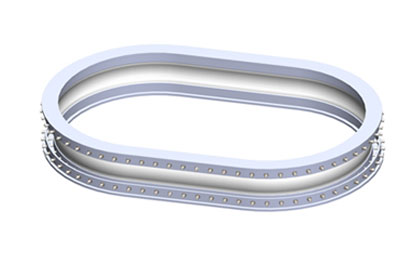

In the CDQ technical process, our company can provide CDQ furnace loading device, furnace electro-vibrating feeder, furnace compensator, furnace water seal groove, furnace lid, electric putter, furnace plate gate, coke dust cooling device and furnace rotary seal valve.