CDQ Furnace Rotary Seal Valve

Introduction of CDQ Furnace Rotary Seal Valve

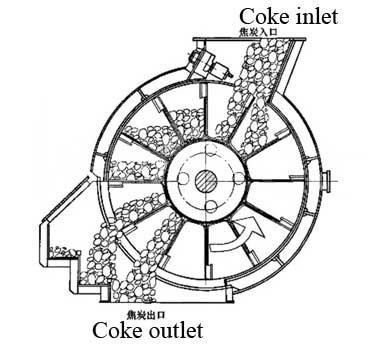

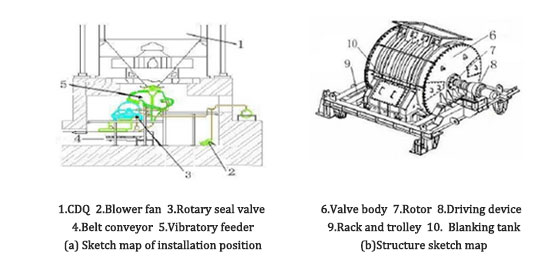

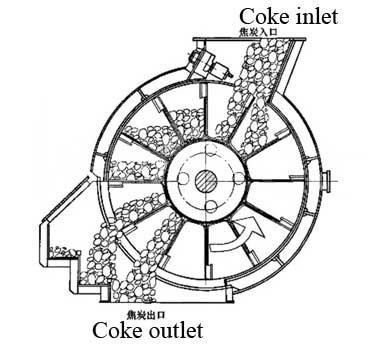

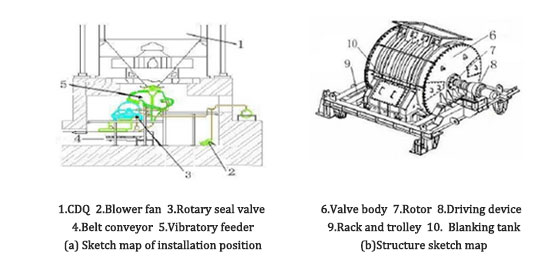

CDQ furnace rotary seal valve is one kind of multi-squared seal feeder, installed below the CDQ furnace electro-vibrating feeder. Cycloidal pinwheel reducer driving the rotor of the CDQ furnace rotary seal valve rotates as a fixed direction, and the rotating rotor discharges CDQ from the CDQ furnace electro-vibrating feeder continuously and hermetically. This equipment can operate long-time and steadily under the CDQ below 200 degree centigrade.

Laser Cutting

Z308025 Radial Drilling Machine

HM4U Equilibrator

The HW XMF series rotary seal valve is currently the most advanced coke discharge equipment in the world. It is installed at the bottom of the dry quenching trough in coking plants and connected to the outlet of the vibrating feeder. This equipment is used to continuously and tightly discharge the accumulated and cooled coke at the bottom of the dry quenching coke without interruption. It is widely applicable in the automation fields of coal, metallurgy, chemical industry, and other industries.

Get a Free Quote Now!

Types of CDQ Furnace Rotary Seal Valve

| Type | Coke discharge ability(T/H) | Seal pressure(kPa) | Driving device |

Gross weight (T) |

||

|---|---|---|---|---|---|---|

| Normal | Maximum |

Motor power (kw) |

Power | |||

| HWXMF-75 | 75 | 85 | 8~12 | 5.5 |

AC 3P 380V±10% 50HZ±0.5HZ |

~15 |

| HWXMF-90 | 90 | 100 | ||||

| HWXMF-100 | 100 | 110 | ~17.5 | |||

| HWXMF-110 | 110 | 121 | ||||

| HWXMF-125 | 125 | 137.5 | ||||

| HWXMF-140 | 140 | 154 | ||||

| HWXMF-150 | 150 | 165 | ||||

| HWXMF-160 | 160 | 176 | ||||

| HWXMF-170 | 170 | 187 | ||||

| HWXMF-180 | 180 | 198 | ||||

| HWXMF-190 | 190 | 210 | ||||

| HWXMF-200 | 200 | 220 | ~20 | |||

| HWXMF-220 | 220 | 242 | ||||

| HWXMF-240 | 240 | 264 | ||||

| HWXMF-260 | 260 |

286 |

||||

Function of CDQ Furnace Rotary Seal Valve

CDQ furnace rotary seal valve discharges CDQ from the CDQ furnace electro-vibrating feeder continuously and uniformly.

Advantages of CDQ Furnace Rotary Seal Valve

- Adopting wear-resisting material, with good lubrication and long service life. Redesign and optimize the fat pipeline; set testing system of reversing valve to alarm Anomalies. Install the sight glass and purge device on the both sides of lateral cavity, to facilitate inspectors to observe the lubrication of sealing pair intuitively. Adopt wear-resisting plate, and use the wear-resisting ceramics on some places, with a more long service life.

- Adopting welding wire to surfacing directly instead of the installation of rotor blade on the partition, this avoids the falling off of the rotor blade, and controls the outside diameter tolerance effectively.

- Using special screws on the checking hole, convenient to operation.

- It can be controlled lonely, and also can be controlled with the PLC in the central control room. It is convenient to operate and overhaul.

- It can be equipped with frequency control cabinet, then it can regulate speed and achieve soft starting, and protect the impact from opening and closing of inertia and extend the equipment lifetime.

Get a Free Quote Now!

Anyang Steel Group Rotary Seal Valve Use Site

Why Choose Hengwei Rotary Seal Valve

- The rotor end plate and the inner lining plate of the shell are made of high hardness, high wear-resistant imported steel plate and wear-resistant ceramics, giving it characteristics such as temperature resistance, wear resistance, long service life, and low maintenance costs.

- The rotary seal valve has excellent sealing performance, effectively controlling the leakage of circulating gas and dust in the dry quenching furnace, stabilizing the pressure of circulating gas in the dry quenching furnace, and achieving the purpose of protecting the environment during normal production.

- The main shaft of the rotary seal valve adopts imported bearings to ensure smooth operation of the valve body, thereby enhancing safety and reliability during use.

- Materials enter through the inlet port and are uniformly discharged continuously through the outlet port after being evenly sliced by the blades on the rotating drum.

- The rotary seal valve is equipped with an automatic grease feeding device, which can provide grease to the bearings of the rotary valve and various lubrication points on both sides of the sealed cavity at regular intervals and in fixed quantities.

Laser Cutting

Z308025 Radial Drilling Machine

HM4U Equilibrator

Working Principle of CDQ Furnace Rotary Seal Valve

When the driving device of CDQ furnace rotary seal valve receives the start signal, cycloidal pinwheel reducer rotates the active sprocket, then power transmits to driven sprocket which installed on the spindle of rotor under the driving of Sleeve roller, finally, the rotor of CDQ furnace rotary seal valve starts to rotate. When CDQ drops from the blanking tube and then enters into CDQ furnace rotary seal valve, throwing troughs throw CDQ to the next equipment. CDQ is sent to the next equipment uniformly. Through this way, the flow of CDQ can be controlled conveniently.

Get a Free Quote Now!

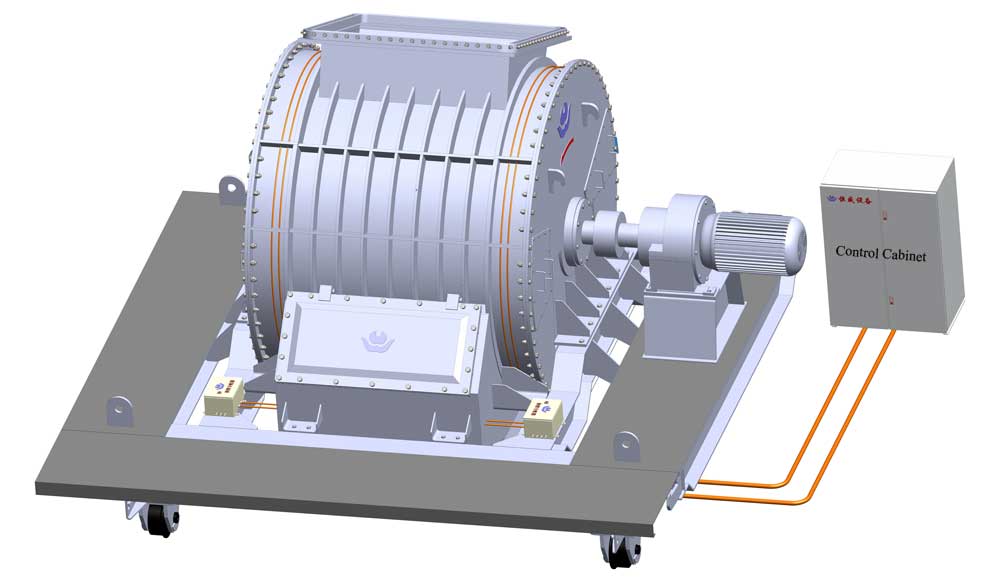

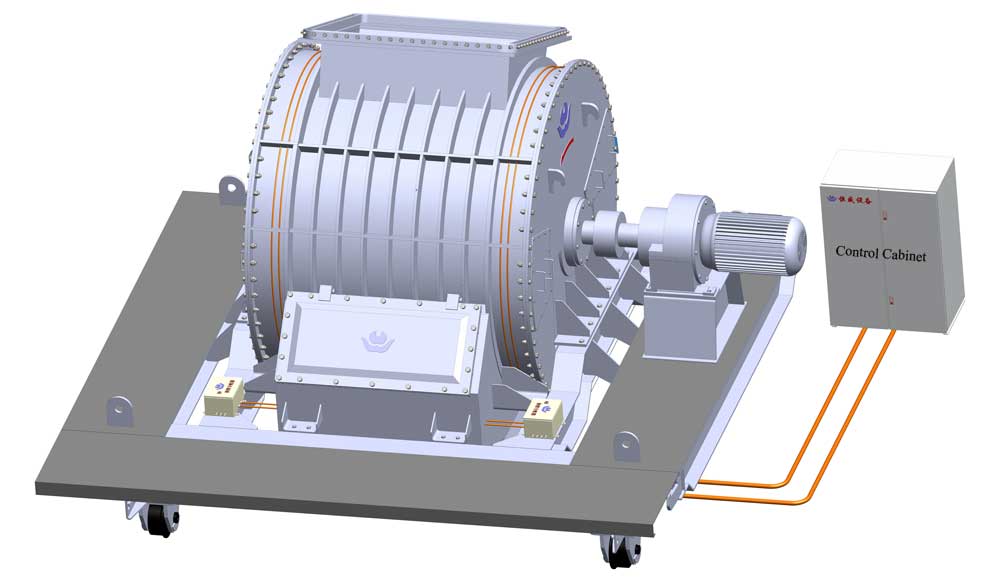

Structure of CDQ Furnace Rotary Seal Valve

-

Overall Structure

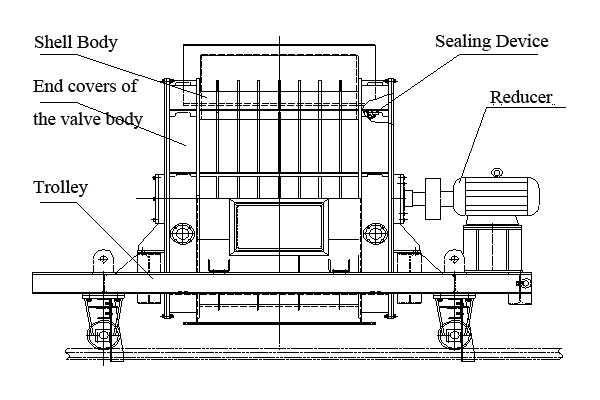

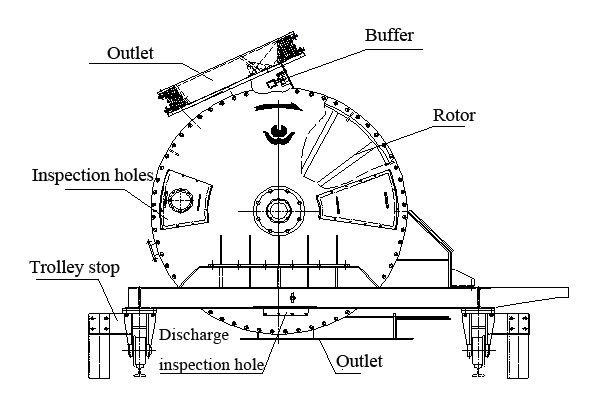

The rotary seal valve is installed on a mobile platform and mainly consists of the rotary seal valve body, drive unit, inlet compensator, lubrication pipeline, and other components. The rotary seal valve includes the shell body, inner lining plate, annular wear-resistant plate, rotor welded with the main shaft, sealing devices on both sides of the rotor, wear-resistant plate in the rotor receiving cavity, and bearing seat with flange. It is mainly composed of valve body, driving device, mobile trolley and the up and down compensator.

- The rotor, coupled with bearings on both end covers of the valve body, forms the rotary seal valve body.

- The rotary seal valve body is mounted on the mobile platform.

- The reducer is connected to the rotor shaft via a coupling, and the rotor is driven to rotate by the reducer motor.

- The cavity between the rotor blades continuously discharges the coke fed from the upper port through the lower port.

- A buffer is installed at the upper port of the rotary seal valve to prevent material jamming.

- End face sealing devices are installed at both ends of the rotor to prevent leakage of harmful gases.

- Sealing inspection holes in the end covers are used for inspection and maintenance of the end face sealing devices.

- Discharge inspection holes at the bottom of the valve body are used to clear debris and ensure smooth discharge pipes.

- There are 6 lubrication points on each side for end face sealing and 1 lubrication point on each end for rotor bearings, totaling 14 lubrication points.

- Automatic lubrication is achieved through the grease system to ensure normal operation and expected lifespan of the equipment.

- Main materials: Rotor and shell body: Q235. Lining: Wear-resistant ceramics. Outlet/inlet lining plate: Wear-resistant cast plate. Rotor top: Tungsten carbide overlay.

-

End Face Sealing Device

- The outer circumference of both ends of the rotor has sealing grooves, where packing and adjusting rings are installed to adjust the sealing.

- The grease is distributed to the whole sealing surface through the oil groove on the contact surface between the static ring and dynamic ring seal.

- The sealing ring is sealed by adjusting the nut in the adjusting device to change the spring pressure.

-

Buffer

- A buffer is installed facing the inlet direction at the inlet port.

- The buffer head is mounted on the buffer support bracket using butterfly springs, and the buffer support bracket is bolted to the shell mounting base. The front end of the buffer head is overlaid with wear-resistant hard alloy.

- The spring force can be adjusted by adjusting the adjusting nut.

- The initial force of each spring group is set to 200kg/group at the factory.

- Functions of the buffer: 1. Flatten and align the coke entering the inlet port to smoothly enter the rotary cavity. 2. In case of large pieces of stuck coke, there should be a relatively slow process to stop the rotor, avoiding sudden stops that may cause damage to the device.

Get a Free Quote Now!

Performance List of CDQ Rotary Seal Valve

| No. | Equipment name | Specifications | Piece/set | Delivery date | Users |

|---|---|---|---|---|---|

| 1 | CDQ Rotary Seal Valve repair in coking plant | 190t/h | 1 | July 2014 | Henan Anyang Iron & Steel Group Co., Ltd. |

| 2 | CDQ Rotary Seal Valve | 140t/h | 1 | October 2014 | Henan Anyang Iron & Steel Group Co., Ltd. |

| 3 | CDQ Rotary Seal Valve | 140t/h | 1 | September 2014 | Handan Iron & Steel Co., Ltd. |

| 4 | CDQ Rotary Seal Valve | 140t/h | 1 | December 2014 | Gansu Jiu Steel Group. Hongxing Iron & Steel Co., Ltd. |

| 5 | CDQ Rotary Seal Valve repair | 140t/h | 1 | September 2015 | Wuhu New Casting Pipe Co., Ltd. |

| 6 | CDQ Rotary Seal Valve repair in coking plant | 75t/h | 1 | January 2016 | Henan Anyang Iron & Steel Group Co., Ltd. |

| 7 | CDQ Rotary Seal Valve repair in coking plant | 190t/h | 1 | January 2016 | Henan Anyang Iron & Steel Group Co., Ltd. |

| 8 | CDQ Rotary Seal Valve repair in coking plant | 140t/h | 1 | April 2016 | Henan Anyang Iron & Steel Group Co., Ltd. |

| 9 | CDQ Rotary Seal Valve repair | 1 | July 2016 | Jiangsu Shagang Group. Co., Ltd. | |

| 10 | CDQ Rotary Seal Valve repair | 140t/h | 1 | October 2016 | Hebei Iron & Steel Group Co., Ltd. |

| 11 | CDQ Rotary Seal Valve repair | 75t/h | 1 | October 2016 | Hunan Valin Xiangtan Iron and Steel Co., Ltd. |

| 12 | New-type CDQ Rotary Seal Valve | 190t/h | 1 | December 2016 | Henan Anyang Iron & Steel Group Co., Ltd. |