CDQ Furnace Electro-vibrating Feeder

What is CDQ Furnace Electro-vibrating Feeder?

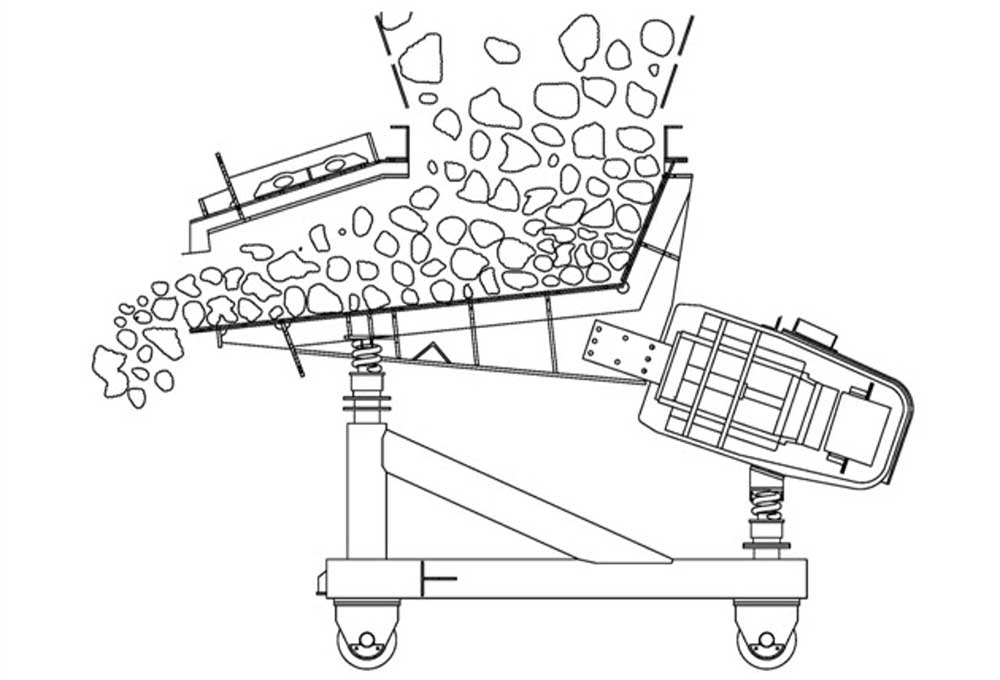

CDQ furnace electro-vibrating feeder is CDQ furnace electromagnetic vibrating feeder, which is a quantitative discharge device of the coke. By adjusting its amplitude and the exciting current magnitude, it can control thereby the discharge amount of the coke. The compensator connected to the lower part of plate gate is to receive the cooling coke from the CDQ furnace and then evenly discharged it. The amplitude and temperature detector is set in the feeder. Don't hesitate to contact us if you are interested in our CDQ furnace electro-vibrating feeder, we sincerely hope to cooperate with coustomers from all over the world! We will try our best to service you, trust us please!

Function of CDQ Furnace Electro-vibrating Feeder

The dynamical system of the CDQ discharge system is installed at the bottom of the cooling section of the CDQ furnace, which is to continuously discharge the cooling coke. In the discharging process, under the vibration of the feeder, the cooling coke is continuously discharged in a quantitative way and flow into rotary sealing valve. And then the coke discharged by rotary sealing valve will be sent to coke screening building through the belt conveyor.

Angang Steel Group 70t/h CDQ Furnace Electro Vibrating Feeder

Angang Steel Group 140t/h CDQ Furnace Electro-vibrating Feeder Repaired

Electro-vibrating Feeder in Bao Steel Company

Electro-vibrating Feeder in Jiangxi Jiujiang

Our Processing Capacity

We have professional technology, excellent stuff and precise equipment. After so many years experience of making coke fuel equipment, our customers are satisfied with our products and service. As the improvement of science and technology, we will produce more sophisticated coke fuel equipment, please believe in us. Our precise equipment is as follows:

Z3080 x 25 Radial Drilling Machine

HM4U Equilibrator

4 Meters CNC Double-column Vertical Lathe

4 Meters CNC Double-column Vertical Lathe CNC Bending Machine

CNC Bending MachineAdvantages of CDQ Furnace Electro-vibrating Feeder

- Magnetic force converted from electric power is used to generate driving force to transmit the material. Compared with other feeding equipments, the feeder is characteristic of high frequency, small amplitude and instantaneous adjustment of discharging amount without abrasion, lubrication, contact and grade.

- No rotating parts; with favorable sealing performance; material tank has passed air tightness test.

- Low maintenance cost; no daily maintenance during the production; only to check the equipment operation during annual maintenance of the CDQ furnace.

- Simple structure, easy operation, no lubrication, lower power consumption, convenient installation and maintenance, and controlled quantitative discharge.

Working Principle of CDQ Furnace Electro-vibrating Feeder

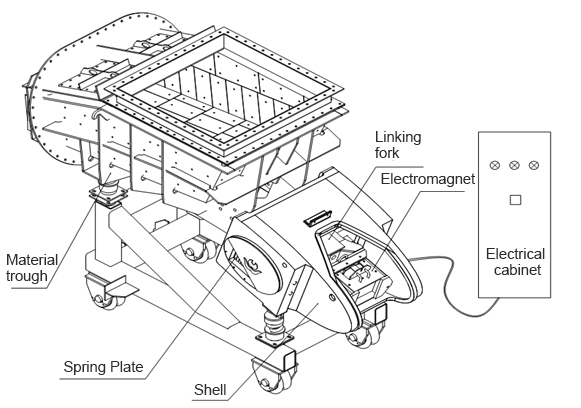

Based on mechanical resonance principle, the electromagnetic vibration feeder is to make double masses work in the sub-resonance state. After the half-wave rectification of silicon controlled rectifier (SCR), there is the current in the coil going through in the positive half wave, and the core will generate a pulsed electromagnetic force to pick up the armature and move the tank backwards and then bring the deformed plate spring a certain potential energy storage; there is no current going through in the negative half wave, and the electromagnetic force will disappear, the potential energy of plate spring will release as well, so the tank will be moved forwards. The feeder makes the reciprocating motion at the frequency of 50Hz so that the coke has to be done the throwing movement in the tank with the inclined angles. The discharge amount of the coke is controlled by adjusting the current.

Structure of CDQ Furnace Electro-vibrating Feeder

Electromagnetic vibrating feeder consists of the following main components: vibrating source, material tank, supporting carriage, control cabinet, guide tank.

Why Choose Hengwei Electromagnetic Vibration Feeder

The Electromagnetic Vibration Feeder features small size, light weight, easy installation and maintenance, no need for lubrication due to absence of rotating parts, low operating costs, long lifespan, and high adaptability to instant changes in feeding quantity, as well as high feeding accuracy.China's steel mills accounts for more than 50% of the world's steel mills, our electromagnetic vibration feeder is used to almost all the steel mills in China. Such as Shanghai Baosteel Group Corporation, Anshan Steel & Iron Group Coking Co., Ltd., Handan Branch of Hebei Steel & Iron Group, China Shougang Group, Ansteel Group Coking Co., Ltd., Henan Anyang Iron & Steel Co., Ltd. etc ; of course there are many coking plants are also using our electromagnetic vibration feeder, such as Meishan Steel & Coking Co., Ltd., Qian’an Jiujiang Coking Co., Ltd., Ltd. , Henan Yulong coking plant, and so large domestic well-known steel coking enterprises.

We have also obtained national patent certificate and provincial certificate of the electromagnetic feeder.

Scientific and Technological Achievements Certificate

The Application of a New Patent Certificate

Performance Table of Electromagnetic Vibration Feeder

| No. | Item | Spec.& Type | Qty. | Contract Time | User |

|---|---|---|---|---|---|

| 1 | Core device replacement of CDQ electromagnetic vibration feeder | 140T | 1 | 2011.8 | Anyang Iron & Steel Co., Ltd. |

| 2 | Electromagnetic vibration feeder | 75T | 1 | 2012.3 | Anyang Iron & Steel Co., Ltd. |

| 3 | Electromagnetic vibration feeder | 75T | 1 | 2012.8 | Handan Branch of Hebei Steel & Iron Group |

| 4 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2012.9 | Meishan Steel & Coking Co., Ltd. |

| 5 | Electromagnetic vibration feeder | 125T/140T | 4 | 2013.1 | Qian’an Jiujiang Coking Co., Ltd. |

| 6 | Core device replacement of CDQ electromagnetic vibration feeder | 170T | 1 | 2013.1 | Xichang Steel & Iron Corp. |

| 7 | Electromagnetic vibration feeder | 140T | 1 | 2013.4 | Hanbao Steel & Iron Group |

| 8 | Electromagnetic vibration feeder | 150T | 1 | 2013.6 | Laiwu Steel & Coking Co., Ltd. |

| 9 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2013.4 | Henan Anyang Steel & Iron Group |

| 10 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2013.6 | Anshan Steel & Iron Group Coking Co., Ltd. |

| 11 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2013.7 | Jinniutian Iron & Coal Coking Co., Ltd. |

| 12 | Electromagnetic vibration feeder | 110T | 1 | 2014.2 | Tangshan Jianlong Steel & Iron Co., Ltd. |

| 13 | Electromagnetic vibration feeder | 140T | 1 | 2014.2 | ACRE Coking & Refractory Engineering Consulting Corporation |

| 14 | CDQ electromagnetic vibration feeder repair | 140T | 1 | 2014.1 | Ansteel Group Coking Co., Ltd. |

| 15 | Electromagnetic vibration feeder | 110T | 4 | 2014.6 | Baoshan Steel & Iron Corp. |

| 16 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2014.10 | Wuhan Steel & Iron Coking Co., Ltd. |

| 17 | Electromagnetic vibration feeder | 140T | 4 | 2014.8 | Zhanjiang Steel & Iron Co. of Baoshan Corp. |

| 18 | Electromagnetic vibration feeder | 160T | 1 | 2014.12 | Tangshan Rongyi |

| 19 | Electromagnetic vibration feeder | 75T | 1 | 2015.1 | Henan Yulong Coking Corp. |

| 20 | Electromagnetic vibration feeder | 150T | 1 | 2015.3 | Liuzhou Steel & Iron Corp. |

| 21 | CDQ electromagnetic vibration feeder repair | 140T | 1 | 2015.11 | Wuhan Steel & Iron Coking Co., Ltd. |

| 22 | CDQ electromagnetic vibration feeder repair | 75T | 1 | 2015.5 | Handan Branch of Hebei Steel & Iron Group |

| 23 | Electromagnetic vibration feeder | 150T | 1 | 2015.7 | Jinan Branch of Shandong Steel & Iron Group Co., Ltd. |

| 24 | Electromagnetic vibration feeder | 190T | 1 | 2015.12 | Anshan Steel & Iron Group Coking Co., Ltd. |

| 25 | CDQ electromagnetic vibration feeder repair | 140T | 1 | 2015.2 | Anshan Steel & Iron Group Coking Co., Ltd. |

| 26 | Electromagnetic vibration feeder | 190T | 2 | 2016.5 | Anshan Huatai CDQ Co., Ltd. |

| 27 | Core device replacement of CDQ electromagnetic vibration feeder | 190T | 1 | 2016.5 | Tongling Pacific Special Material Co., Ltd. |

| 28 | Electromagnetic vibration feeder | 140t/h | 4 | 2016.7 | Shandong Iron & Steel International Co., Ltd. |

| 29 | Electromagnetic vibration feeder | 1 | 2016.8 | Wuhu Xinxing Pipe Casting Co., Ltd. | |

| 30 | CDQ electromagnetic vibration feeder repair | 75t | 1 | 2016.8 | Handan Branch of Hebei Steel & Iron Group |

| 31 | Electromagnetic vibration feeder | 140t/h | 1 | 2016.10 | Liuzhou Steel & Iron Corp. |

| 32 | Electromagnetic vibration feeder | 190 | 1 | 2016.9 | Henan Anyang Iron & Steel Co., Ltd. |

| 33 | electromagnetic vibration feeder repair | 140t/h | 1 | 2016.10 | Henan Anyang Iron & Steel Co., Ltd. |

| 34 | Electromagnetic vibration feeder | 170t/h | 1 | 2016.11 | (China Xuyang Coal Co., Ltd.) |

| 35 | Electromagnetic vibration feeder | 150t/h | 1 | 2017.2 | Jilin Jianlong Steel & Iron Co., Ltd. |